Why does lithium battery pack need aging test?

Lithium battery pack aging test is an indispensable procedure in the production process of lithium batteries. It is to better evaluate battery life and performance attenuation, so as to ensure the stability and reliability of factory batteries.

What is battery aging test ?

The battery aging test is a test that simulates the actual use of the battery, performs charge and discharge cycles on the battery, and records the performance of the battery. This kind of test is generally divided into normal temperature aging and high temperature aging. As the name implies, the battery is placed under normal temperature and high temperature conditions for charge and discharge cycle testing. In the battery aging test, the general test indicators involve the internal resistance, voltage and capacity of the battery, and these data are of great significance for the evaluation of the battery.

The purpose of the aging test

The purpose of aging test can be mainly explained from two aspects: enterprise and product.

From a enterprise perspective, product quality is an important factor that affects the company’s survival, and aging test is an important step in detecting battery quality. Only through battery aging test can the quality of the battery be guaranteed and customers can use high-quality products, high safety battery.

From the perspective of the product itself, the aging test can allow the electrolyte in the lithium battery to infiltrate better and the battery to react more completely; at the same time, it accelerates some side effects that may occur in the battery, allowing the lithium battery to reach the temperature state faster. The aging test can also expose some defective products in lithium batteries, making it easier to screen out lithium batteries with high consistency in the later stage, ensuring product quality.

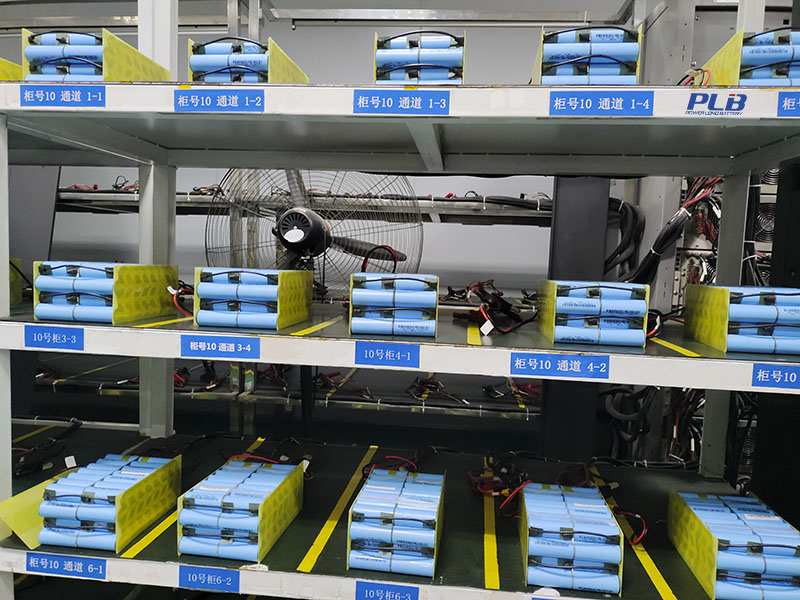

To sum up, the importance of aging test of lithium battery packs is self-evident. As a professional lithium iron phosphate battery manufacturer, PLB has invested a lot of time and cost in aging test and established a professional aging workshop. We purchased a variety of aging cabinets from well-known brand manufacturers to meet the aging requirements of various battery packs, including: 15V/20A, 30V/10A, 60V/20A, 65V/20A, 75V/20A, 100V/15A, 100V/20A, 100V/ 100A, 750V/300A and these aging cabinets can meet the aging test of various battery packs below 750V/150A. At the same time, after more than ten years of development, PLB has accumulated rich aging experience, established a standardized aging process, and implemented digital management to continuously improve product quality, allowing customers to buy and use with confidence!

Article source:https://www.powerlongbattery.com/why-does-lithium-battery-pack-need-aging-test

评论

发表评论